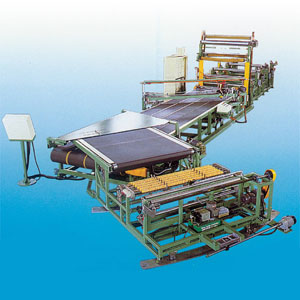

Horizontal Type Bias Cutter

Modal: p056

AW-HB-IA-M2

Features

While the cutting width is too wide, it is very difficult to splice the cutted ply. Horizontal bias cutter with a specially designed return-type splicing and winding conveyor. This design makes it very easy for one operator to splice the wide-cut ply.

Function

- At pre-set cutting angle and pre-set cutting width, automatic operation.

- Cutting width of nylon cord is controlled by digital counter.

- Cutting accuracy:machine accuracy ±1mm.

- Special designed driving system for long time working/ less maintenance/ less energy consumption on cutting device.

- Cutting angle is adjusted by motor.

- The nylon cord roll & liner cloth roll are locked by auto chuck on let-off unit. There is a disc brake by 3 steps air pressure for keep suitable tension force while fabric roll diameter is reduced.

- There are two banana rolls on festoon unit to prevent the nylon cord shrinkage and stick together.

- Anti-stick and auto. Separating device for nylon cord and liner cloth.

Special Function by Optional Attachment

Let-Off Unit

- 3 step tension control: The fabric roll will keep the suitable tension when the diameter is changed.

- There is a splicing table for splice the end of exist nylon cord & top of next nylon cord. One photo switch can inspect and auto. Tear the line cloth to separate from fabric while sticked together on let out.

- There is a constant torque motor on the top position of festooner to keep the nylon cord at the most suitable tension force to avoid the nylon cord shrinking and sticking together.

- There is a ED-2 unit on dancing roll unit to control the constant speed of nylon cord from let-off unit.

It is non-stop control type, which willl increase or reduce the nylon cord supplying speed automatically.

So the accuracy of cutting width will be much better.

Main Conveyor

- Spacial anti-stick belt conveyor, which was imported from Europe

- The conveyor is drove by AC serve motor which can make low speed start-high speed movement-slow down speed to stop to control the precision accuracy cutting witdh of nylon cord.

- The cutting unit is installed on 2 pcs of slide bearing and drove by AC motor with inverter control, which can make fast movement and long-term operation without part replacement.

- Cutting angle is adjusting by gear motor. There is a encorder for pre-setting controlling the cutting angle.

- The position of cutting device is moveable by motor with disc brake device to control the center of cutted nylon cord same as center of splicing table.

Wind Up Unit

- Omini roller with guide plate on the festoon position for centering the nylon cord. The liner cloth let-off unit is equipped with E.P.C. Control to keep the liner cloth and cord in the center position while wind up.

It will promote the quality and efficiency on tire building machine.

Electric Control System

- This maching is controlled by TOUCH SCREEN and PLC. The cutting width and cutting angle for each different size of nylon cord can be key in on touch screen and save. When size is changed. it onlly needs to key in specification of size, then the cutting angle and cutting width will be changed sutomatically.

- The cutting number can be pre-set in advance. The pre-set cutting number and un-cut nylon cord number will show on the touch screen. On the youch screen, the pre-set cutting number will reduce one piece if one piece is cutted. Therefore, it can control the demanded cutting number for each day very precisely, which is very convenient for production quantity control.